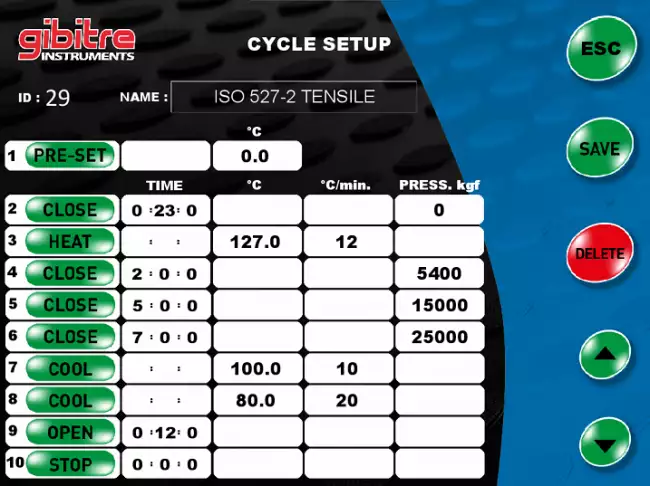

Setups of Moulding Cycles

The PLC for press control permits to set moulding cycles for each need

Cycles List

Up to 40 cycles can be stored in the PLC.

The cycles can be saved in the Gibitre Standard database through the Gibitre_Press_Control software.

Cycle Preparation

Each cycle allows you to enter up to 30 operations of:

- Mold opening

- Mold closure

- Wait

- Plates heating

- Platens Cooling

By pressing the green button for each line of the cycle-preparation page you can select the type of operation to be performed and activates the corresponding setting parameters.

Displacement Functions: Open, Close, Wait

The commands allow you to manage the operations of mold closing, degassing, waiting during the vulcanization time, opening at the end of the cycle.

For all these operations it is possible to define the command execution time by setting the time in minutes, seconds and tenths of a second.

Closure with Controlled Force

If your press is equipped with the Closing Force Control option, it is possible to prepare molding cycles by defining the force to be applied to the mold in each step.

In this case the menu allows you to define both the duration and the force to be applied for each cycle step.

The definition of the duty cycle can be combined with the definition of the thermal cycle to obtain elaborate combined cycles.

Temperature Control: Pre-set

For each molding cycle you can define the Pre-set temperature to which the machine must be adjusted before the activation of the molding cycle is enabled.

This function guarantees repeatable molding conditions and high repeatability of the results obtained.

When the press is used in combination with the Gibitre Press-Control software, the preparation of the machine is carried out automatically based on the queue of products to be printed set in the software.

The tolerance limits for reaching the expected pre-set temperature can be set as needed.

Temperature Control: Heating

Each heating step within a molding cycle allows to define:

- The temperature to be reached

- The thermal gradient (° C / min) with which to reach the required temperature. The temperature control PLC automatically adjusts the heating to achieve the required temperature change rate.

The heating elements installed on the press allow to obtain a Thermal Gradient up to 15 °C/min (the thermal mass of the mold and of the product to be heated can reduce the real heating rate obtainable).

In the same cycle, several temperature set operations can be inserted to configure the desired thermal cycle.

If the thermal gradient is not defined, the heating rate is optimized to reach the desired temperature in the shortest possible time.

Temperature Control: Cooling

The cooling of the tops is necessary for the molding of thermoplastic products.

If your press is equipped with a cooling device, it is possible to set the automatic cooling phases of the plates.

Each cooling step within a molding cycle allows to define:

- The temperature to be reached

- The thermal gradient (° C / min) with which to reach the required temperature. The temperature control PLC automatically adjusts the flow of the cooling fluid independently in the two planes to achieve the required temperature change rate.

Gibitre Instruments

Via dell'industria, 18

Bergamo (Italy)

te. +39 035 461146

www.gibitre.it

info@gibitre.it

Copyright Gibitre Instruments