Control of Closure Force for Lab Press

Optional setup for Gibitre Lab Press for the control of the closure force during the moulding cycle

Overview

The Digital pressure regulation system is designed for applications that require an accurate control of closure force.

The control of the closure force permits to have a complete control of the moudling cycle of Gibitre Laboratory Press in order to prepare samples which require a accurate control of force and temperature during the moulding cycle.

For which applications you need to control the closure force ?

Examples of applications are:

- preparation of samples for testing of adhesion/bonding properties: adhesion force is related with the force applied during the preparation of the sample. Accurate force control is needed to obtain repeatable results during production control and for the study of the properties of the product during research and development.

- preparation of samples with several types of thermoplastic products which require a specific moulding cycle with step-by-stem application of closure force.

- preparation of multi-layer samples where the diferent layers need to be applied one on the top of the other using a specific force and temperature

- measure of the force-deformation properties in compression when a specified force and temperature cycle is applied.

For which applications you DON'T need to control the closure force ?

The Digital pressure regulation is not needed for standard moudling of rubber of thermoplastic samples.

For standard applications, the international standards only specify the minimum pressure to be applied to ensure the correct preparation of the samples.

In this case, the standard press, which closed the plates with the maximum available closure force (25 Tons) will fulfill your needs.

The material in excess inserted in the mould will be evacuated from the mould during the closure of the mould.

How does the closure force regulation system works ?

A 2-stages hydraulic circuit, which includes proportional regulation valves and which has been specifically designed for Gibitre press is installed instead of the standard 1-stage circuit.

The first hydraulic system controls the displacements of the platen, while the second performs continuous fine pressure regulation during the complete moulding cycle

The results is a smooth and consistent force control which permit to set the closure force between 10 kN and 250 kN with 10 N set force regulation steps with regulation oscillations lower than 1000 N.

Setup of the Moudling cycle

The control of the closing force is performed using the Automatic Press Control that must be installed in combination with the Closure Force Control option.

The PLC controller for the press is provided with a user-friendly Touch Screen Display and permits the free definition of the moulding cycle by setting:

- the displacements of the moving platen of the press,

- the closure force for each closure step.

- the temperatures of the platens (a specific temperature and thermal gradient can be set for each step)

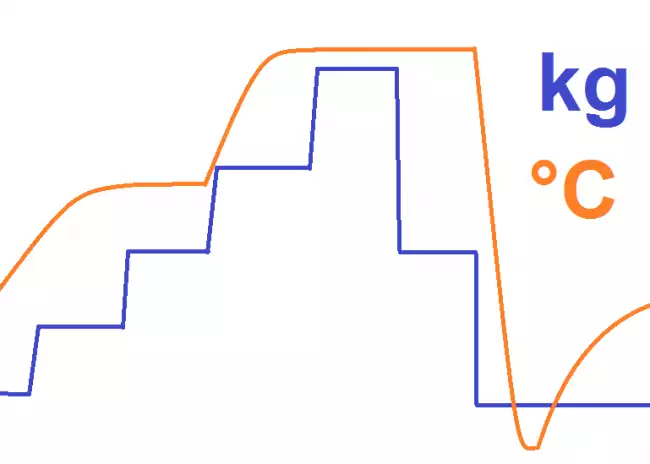

Three Moulding cycles can be stored. Each cycle includes 24 moulding steps (including displacements, temperatures setups and pressure setups)set multiple pressure regulation steps within the moulding cycle.

As a result, you can prepare totally customized moulding cycles, which include multiple temperature and multiple force steps !

Calibration of the Closure Force

The closure force system is calibrated using a reference force sensor which is placed between the platens of the press.

The Calibration certificate supplied with the machine includes the calibration of the force at several force application streps.

Closure force Control (option)

Continuous control of the closing force with regulation between 10 and 250 kN with 10N regulation steps. Max. regulation error: 1 kN.

Gibitre Instruments

Via dell'industria, 18

Bergamo (Italy)

te. +39 035 461146

www.gibitre.it

info@gibitre.it

Copyright Gibitre Instruments