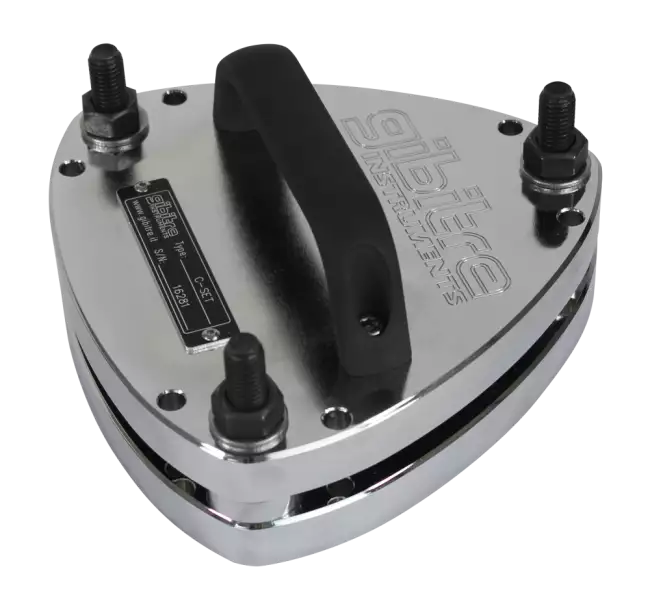

Compression Set - Drive

A new construction of the device for efficient preparation and reliable results

Standards the instrument complies with:

ASTM D1056; ASTM D1414; ASTM D3574; ASTM D3575; ASTM D395-B; EN 681-1; FIAT 50410; ISO 815; ISO 1856; ISO 6916-1; ISO 6916-2;

ASTM D1056; ASTM D1414; ASTM D3574; ASTM D3575; ASTM D395-B; EN 681-1; FIAT 50410; ISO 815; ISO 1856; ISO 6916-1; ISO 6916-2;

About Compression Set Test

This Compression Set device complies with ISO 815, ASTM D 395 Method B, DIN 53 517 standards.

The Compression Set Test methods are intended to measure the ability of rubbers to retain their elastic properties at specified temperatures after prolonged compression at constant strain (normally 25 %) under specific Temperaure and Deformation conditions.

For rubber of nominal hardness within the range 10 IRHD to 80 IRHD 25 % strain is normally used. For hardness of 80 IRHD and above, a lower compression strain is used: 15 % for a nominal hardness from 80 IRHD to 89 IRHD and 10 % for a nominal hardness from 90 IRHD to 95 IRHD.

Key Features

• Usable area optimized for 12 specimens

• Instrument setups with 2 or 3 plates

• Aluminum handle for one-hand manipulation

• 3-bolt lock for quick preparation

• Support base for screwdriver use

• Chrome-plated plates with standard roughness

• Calibration report for roughness and spacers thickness

• Circular anti-fall spacers

• Rubber feet

How to perform a test

To perform a test:

1) Insert the samples between the test plates

2) insert the 3 spacers requestd to obtain the expected deformation

3) Close the bolts until the plates come in contact with the spacers to apply the expected deformation

4) Place the whole device in an oven at the set temperature and for the desired test time

5) Remove the device from the oven and mesure the permanent deformation using the procedure described in the standards

Optional Compression Set Software: Store your Results!

The software allows to acquire the thickness measurement from the comparator (connected via USB cable) and to calculate the results of the Compression Set tests.

In particular, the software allows you to:

• identify the specimens

• select the specimen processing method that was used

• enter the initial and final thickness of each specimen and the thickness of the spacer used

• Calculate the Compression Set value obtained in compliance with the standards

• Compare the result with the tolerance limits and save the results in the Gibitre SQL standard database

• Produce Reports and Statistics.

Calibration Report for Compression set device

The Compression Set device is equipped with a unique identification label and is supplied with a Calibration Report with traceability to the reference instruments used.

The Calibration Report includes the measurements of:

• Surface roughness of the device in accordance with the requirements of the standards.

• Spacer thicknesses measured in 3 points.

Aluminum handle and optimized size for easier manipulation

Compression set devices require frequent movements and manipulations and must be placed in stoves. Being able to manipulate the instrument with one hand is certainly an advantage.

The solid anodized aluminum handle improves handling but does not increase the volume occupied in the stove.

The size and thickness of the plates have been designed to ensure the necessary rigidity while maintaining a low weight: 11.5 kg for the 3-plate device and 8 kg for the 2-plate device.

Closure with 3 bolts

The device allows the closing of the upper plate using only 3 bolts. The bolt head is recessed into the base plate to avoid the use of two wrenches.

3-bolt closure reduces preparation time by 25%.

Three plate device construction

The 3-plate model is optimal for performing large quantities of tests in one run, allowing up to 24 ISO 815-1 Type A specimens to be tested simultaneously.

For changing control needs, the intermediate plate can be added or removed.

The total weight of the assembled device is 11,5 kg

Two plate device construction

The 2-plate model is versatile and light, allows you to test up to 12 ISO 815-1 Type A specimens simultaneously and is optimal for laboratories where specimens arrive in staggered fashion.

The total weight of the device is 8 kg.

Optimized surface for numerous specimens

The usable surface of the devices allows to test up to 12 ISO 815-1 type A specimens.

A rectangular device with the same surface could only accommodate 8.

Support base: Assembly and Opening of the device Quick and Safe

The assembly and opening operation of the device can be tiring and not without risks.

The support base, specially designed to be locked in a vice, ensures that the device does not move during operations and allows you to use the automaic screwdriver to avoid the use of wrenches: a pit stop for your Compression set.

Mould for samples

• Mould for sample prepation

• Thickness meter for the measure of sample thickness

Interchangeable silicone feet: safer handling and attention to the laboratory

The reduction in the number of sharp and angular surfaces helps to reduce the risk of shocks and noise during numerous manipulations of the devices.

Equilateral triangle construction

The shape of the equilateral triangle device and the thickness of the 18 mm plates eliminates the risk of deformation of the plates even with a large number of specimens with high hardness and guarantees to apply the same deformation to all specimens.

Development and production

The instrument is totally developed and produced in the plant of Gibitre Instruments in Italy.

All the mechanical parts are produced in the company workshop using modern CNC machines.

Components and sensors from well-known brands are selected in order to ensure the maximum reliability in the measures

Internal trained personnel takes care of all the production stages: assembly, start-up, calibration, packing, shipment and installation.

Testing Configuration

Dimensions of the assembled device

Device with 3 Plates:(WxDxH) 182x184x123 mm

Device with 3 Plates:(WxDxH) 182x184x93 mm

Device with 3 Plates:(WxDxH) 182x184x93 mm

Number of plates

2 or 3

Usable surface / Samples for layer

100 cm2 - 12 Samples (with 29 mm diam.)

Standard Spacers (Big sample)

ISO 815 Type A: 9,35 mm ± 0,05 mm

ASTM D 395 Type 1: 9,5 mm ± 0,02 mm

DIN 53 517-II: 9,38 mm ± 0,01 mm

ASTM D 395 Type 1: 9,5 mm ± 0,02 mm

DIN 53 517-II: 9,38 mm ± 0,01 mm

Standard Spacers (Small sample)

ISO 815 Type B: 4,75mm±0,05mm

ASTM D 395 type 2: 4,5mm±0,01mm

DIN 53 517-I: 4,72mm±0,01mm

ASTM D 395 type 2: 4,5mm±0,01mm

DIN 53 517-I: 4,72mm±0,01mm

Technical specifications

Construction Characteristics

Chrome-plated steel plates with 18 mm thickness.

Roughtness of the plates

Ra < 0.4 µm

Calibration

Calibration report with traceability to the instruments used. Calibration includes:

- Measurement of surface roughness

- Measurement of the thickness of the spacers

- Measurement of surface roughness

- Measurement of the thickness of the spacers

Weight of complete device

Device with Two Plates: 8 kg

Device with 3 Plates: 11.5 kg

Device with 3 Plates: 11.5 kg

Bolts for Closure

N ° 3 Bolts for high temperature M12. The screws are recessed in the device to allow quick closure with screwdriver

Gibitre Instruments

Via dell'industria, 18

Bergamo (Italy)

te. +39 035 461146

www.gibitre.it

info@gibitre.it

Copyright Gibitre Instruments