Switchable Hardness Measuring Heads

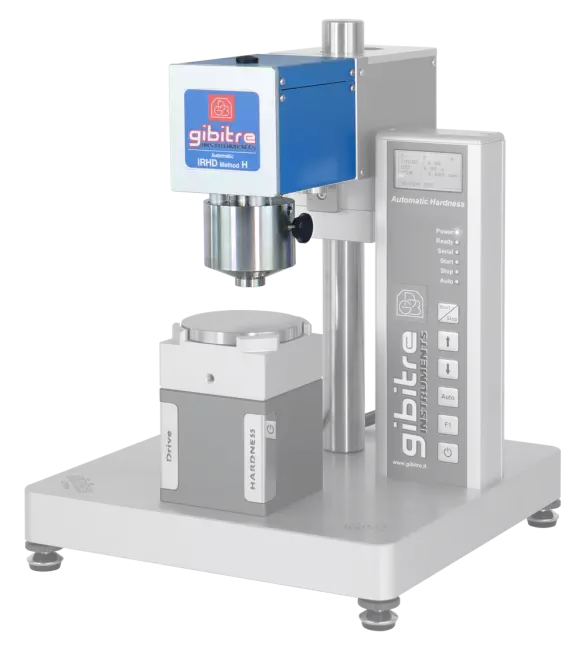

Shore and IRHD Measuring Heads for Hardness Tester Automatic Hardness Check - Drive

Many instruments in one

The Universal Support for Automatic Hardness Testers in Drive version allows all available Shore and IRHD type heads to be applied.

Replacing measuring heads is the ideal solution for research centers with a need to measure against numerous measuring scales or for companies that predominantly use a specific measuring scale and need to carry out occasional checks against other scales.

Many instruments in one

The solid quick coupling system allows the head to be replaced in seconds while ensuring its perfect pependicularity with respect to the support base.

To replace the measuring head:

- Unscrew the locking screw

- Remove the connecting cable

- Replace the head with the desired one

- Insert the connection cable.

The instrument automatically recognizes the applied head and is immediately ready for testing.

Available Hardness Units

The Hardnedd units available are:

Shore A,

Shore D,

Shore A0,

Shore 00,

Shore AM (micro),

IRHD-Micro,

IRHD-Normal,

IRHD-Hard,

IRHD-Low.

Complete hardness testers for simultaneous use

For companies that need to perform systematic production checks against several different measurement scales (e.g., Shore A and Micro-IRHD), it is necessary for durometers to be available at the same time to perform measurements at the required scale.

The optimal solution we propose for such cases is the installation of multiple complete hardness testers connected to the same PC with a single software license. In this way the instruments can be used simultaneously and by several operators without any interruption.

Automatic performance of multiple tests on the sample

International standards require the performance of multiple hardness tests on the specimen and the calculation of the median value.

• The specimen holder plate with motorized rotation allows multiple tests to be performed automatically at different points on the specimen.

• The operator can set the number of tests to be performed automatically on the specimen and the angle of rotation between successive tests.

Accredia Calibration of the hardness units

Each Hardness Unit can be supplied with an ACCREDIA calibration certificate issued by the Accredia laboratory of Gibitre instruments.

The calibration is carried out according to the Technical Procedure approved by Accredia and in compliance with the requirements of the ISO 48-2 (IRHD), ISO 48-4 (Shore A) and ISO 868 (Shore D) standards.

The Calibration refers to:

• Dimensions of the Indentor and Annular foot

• Forces applied by the indentor and the annular foot

• Displacement of the indenter

• Duration of the test

Development and production

The instrument is totally developed and produced in the plant of Gibitre Instruments in Italy.

All the mechanical parts are produced in the company workshop using modern CNC machines.

Components and sensors from well-known brands are selected in order to ensure the maximum reliability in the measures

Internal trained personnel takes care of all the production stages: assembly, start-up, calibration, packing, shipment and installation.

Type of Hardness units

SHORE UNITS

Shore A

Standards: ISO 48-4, ASTM D2240

Application: Soft Rubber, Plastics, Elastomers

Sample standard thickness: 6 mm

Application: Soft Rubber, Plastics, Elastomers

Sample standard thickness: 6 mm

Shore A

Indentor Force: 8.05 N (at 100 Shore)

Contact force: 1000 g

Indentation: 2.5 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Contact force: 1000 g

Indentation: 2.5 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Shore D

Standards: ISO 48-4, ASTM D2240, ISO 868

Application: Hard Rubber, Thermoplastics

Sample standard thickness: 6 mm

Application: Hard Rubber, Thermoplastics

Sample standard thickness: 6 mm

Shore D

Indentor Force: 44.5 N (at 100 Shore)

Contact force: 5000 g

Indentation: 2.5 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Contact force: 5000 g

Indentation: 2.5 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Shore A0

Standards: ISO 48-4

Application: Light Foams, Sponge Rubber, Gels, Human Tissue

Sample thickness: 6 mm

Application: Light Foams, Sponge Rubber, Gels, Human Tissue

Sample thickness: 6 mm

Shore A0

Indentor Force: 8.05 N (at 100 Shore)

Contact force: 1000 g

Indentation: 2.5 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Contact force: 1000 g

Indentation: 2.5 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Shore 00

Standards: ASTM D2240

Application: Light Foams, Sponge Rubber, Gels, Human Tissue

Sample thickness: 6 mm

Application: Light Foams, Sponge Rubber, Gels, Human Tissue

Sample thickness: 6 mm

Shore 00

Indentor Force: 1.111 N (at 100 Shore)

Contact force: 400 g

Indentation: 2.5 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Contact force: 400 g

Indentation: 2.5 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Shore AM

Standards: ISO 48-4, ASTM D2240

Application: Small Technical Articles, O-rings

Sample thickness: 1.5-6 mm

Application: Small Technical Articles, O-rings

Sample thickness: 1.5-6 mm

Shore AM

Indentor Force: 0.76 N (at 100 Shore)

Contact force: 250 g

Indentation: 1.25 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

Contact force: 250 g

Indentation: 1.25 mm

Measurement Range: 0-100 Shore

Resolution: 0.01 Shore

IRHD UNITS

IRHD-M (MICRO)

Standards: ISO 48-2, ASTM D1415

Application: Small Technical Articles, O-rings

Sample thickness: 1-5 mm

Application: Small Technical Articles, O-rings

Sample thickness: 1-5 mm

IRHD-M (MICRO)

Pre-Load: 8.3 mN

Total Load: 153.3 mN

Anular Foot: 235 mN

Indentation: 0.3 mm

Measurement Range: 30-100 irhd

Resolution: 0.01 irhd

Total Load: 153.3 mN

Anular Foot: 235 mN

Indentation: 0.3 mm

Measurement Range: 30-100 irhd

Resolution: 0.01 irhd

IRHD-N (NORMAL)

Standards: ISO 48-2, ASTM D1415

Application: Rubber Parts with Hardness >30 irhd

Sample thickness: 8-10 mm

Application: Rubber Parts with Hardness >30 irhd

Sample thickness: 8-10 mm

IRHD-N (NORMAL)

Indentor Diamater: 2.5 mm

Pre-Load: 0.3 N

Total Load: 5.7 N

Anular Foot: 8.3 N

Indentation: 1.8 mm

Measurement Range: 30-85 irhd

Resolution: 0.01 irhd

Pre-Load: 0.3 N

Total Load: 5.7 N

Anular Foot: 8.3 N

Indentation: 1.8 mm

Measurement Range: 30-85 irhd

Resolution: 0.01 irhd

IRHD-H (HIGH HARDNESS)

Standards: ISO 48-2, ASTM D1415

Application: Hard Rubber Parts with Hardness >85 irhd

Sample thickness: 8-10 mm

Application: Hard Rubber Parts with Hardness >85 irhd

Sample thickness: 8-10 mm

IRHD-H (HIGH HARDNESS)

Indentor Diamater: 1.0 mm

Pre-Load: 0.3 N

Total Load: 5.7 N

Anular Foot: 8.3 N

Indentation: 0.44 mm

Measurement Range: 85-100 irhd

Resolution: 0.01 irhd

Pre-Load: 0.3 N

Total Load: 5.7 N

Anular Foot: 8.3 N

Indentation: 0.44 mm

Measurement Range: 85-100 irhd

Resolution: 0.01 irhd

IRHD-L (LOW HARDNESS)

Standards: ISO 48-2, ASTM D1415

Application: Soft Rubber Parts with Hardness <35 irhd

Sample thickness: 8-10 mm

Application: Soft Rubber Parts with Hardness <35 irhd

Sample thickness: 8-10 mm

IRHD-L (LOW HARDNESS)

Indentor Diamater: 1.0 mm

Pre-Load: 0.3 N

Total Load: 5.7 N

Anular Foot: 8.3 N

Indentation: 0.09-1.1 mm

Measurement Range: 10-35 irhd

Resolution: 0.01 irhd

Pre-Load: 0.3 N

Total Load: 5.7 N

Anular Foot: 8.3 N

Indentation: 0.09-1.1 mm

Measurement Range: 10-35 irhd

Resolution: 0.01 irhd

Gibitre Instruments

Via dell'industria, 18

Bergamo (Italy)

te. +39 035 461146

www.gibitre.it

info@gibitre.it

Copyright Gibitre Instruments