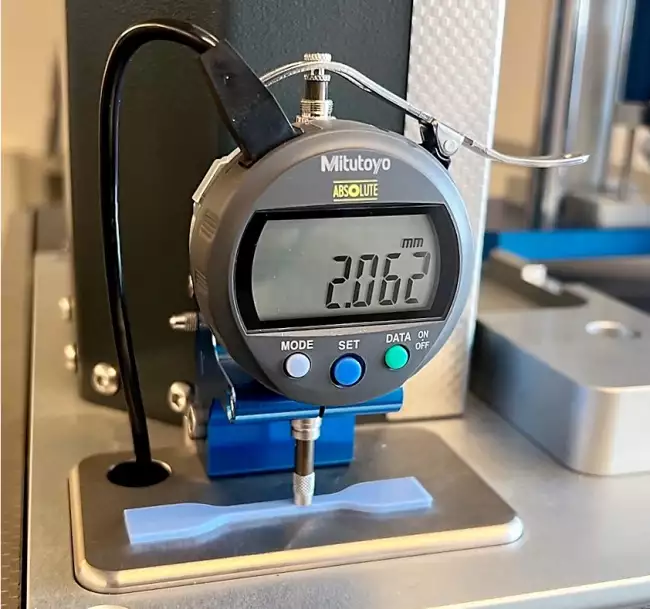

Thickness Meter for Tensor Check

This convenient option allows you to meet the requirements of the standards and drastically reduce the insertion times of the thickness of the specimen

Standards the instrument complies with:

ASTM D3767; ISO 23529;

ASTM D3767; ISO 23529;

Overview

Performing tests on specimens requires the insertion of the thickness or section measurement of the individual specimen for the correct execution of the calculations.

International standards (e.g. ISO 23529 or ASTM D3767) specify:

• Pressure to be applied to the specimen

• Shape of the indenter

• Number of points to measure

• Resolution of the measuring instrument

The feeler gauge integrated with the TensorCheck dynamometer meets the requirements of the standards and drastically reduces the insertion times.

Characteristics of the Integrated Thickness meter

• The dial gauge is mounted directly on the left side of the instrument to facilitate its use.

• Sending data to the software is activated by pressing the 'Enter' button on the main panel of the instrument.

• When all the thickness measurements relating to a specimen have been entered, the 'Next' button on the main panel of the instrument allows you to go to the next specimen without the need to interact with the PC

• The dial gauge has 0.001 mm resolution

• The dial gauge applies the pressure required by the standards to the specimen.

• The comparator tip can be replaced according to the type of specimen and the reference standard.

Insert Sample Thickness

The instrument can be equipped with a digital thickness gauge for direct insertion of the specimen thickness.

The software:

• Receives the thickness measured in several points

• Calculate the average thickness (or minimum or median according to the norm)

• Calculates the section of the specimen based on the calculation formula defined for the type of specimen in use.

The integration with the thickness gauge allows to insert the section of the whole series of specimens that you have to try in a few seconds.

Thickness meter for high-thickenss samples

A thickness gauge version with 50 mm stroke is available to allow the measurement of high thicknesses. The device allows to measure the thickness of specimens in expanded material.

Force applied to the Sample

Between 0.2 and 0.5 N

Resolution

0.001 mm

Gauge Tips supplied

• Flat tip Diameter 5 mm

• Spherical tip (sphere Diam 3 mm)

• Flat tip diameter 7 mm (option)

• Spherical tip (sphere Diam 3 mm)

• Flat tip diameter 7 mm (option)

Integration with the instrument

RS 485 protocol

Gibitre Instruments

Via dell'industria, 18

Bergamo (Italy)

te. +39 035 461146

www.gibitre.it

info@gibitre.it

Copyright Gibitre Instruments