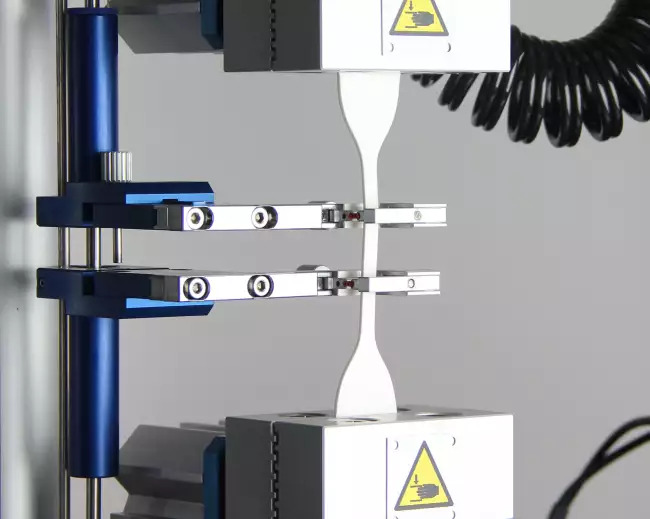

Mechanical extensometer for Tensor-Check

Mechanical extensometer for Tensor-Check

Standards the instrument complies with:

ASTM D412; ASTM D638; ISO 37; ISO 5893; ISO 527-1;

ASTM D412; ASTM D638; ISO 37; ISO 5893; ISO 527-1;

Overview

The differential strain gauge is necessary for the execution of elongation tests on Rubber and Plastic specimens. The device allows measuring the elongation of the linear part of the specimen according to the provisions of the standards (see ISO 37, ISO 527, ASTM D 412, ASTM D 638)

Construction characteristics

The extensometer produced by Gibitre has been specifically developed for testing rubber and elastomers taking into consideration:

• the high elongation that can reach rubber and thermoplastic specimens

• the mechanical strength needed to absorb the energy transmitted to the device when the specimen breaks

• the need to easily change the distance between the clamps (reference length) according to the type of specimen

• the need to adjust the closing force of the tweezers at the base to the type of material to be tested.

Operation

The device has two tweezers with an initial distance (reference lenght L0) defined by the standard for the type of specimen in use. The tweezers are attached to the linear portion of the specimen to measure its percentage elongation, with respect to the reference lenght, during the test.

The device complies with the requirements of ISO 5893.

Adjustment of the distance between the tweezers

The distance between the terminals of the strain gauge can be changed in a few seconds by screwing the required spacer into the appropriate hole in the upper strain gauge.

Spacers for 10mm, 20mm, 25mm and 50mm are supplied, together with the device. Different spacers can be supplied on request.

The spacers are calibrated and the actual distance obtained between the terminals is documented in the Calibration Report supplied with the instrument.

In addition, the construction methods of the Gibitre strain gauge allow the customer to simply check the distance between the clamps using standard flat-parallel blocks.

Tweezers for extensometer

The standard supply of the device includes contact points of the tweezers made of stainless steel. The radius at the point of contact with the specimen has been optimized to prevent slipping during the test while avoiding the risk of scoring the specimen at the contact point.

For materials with very low hardness, expanded materials or products with very slippery surface, additional grips with rubberized contact points can be provided.

Rotating extensometer support

To carry out tests that do not require the use of the strain gauge, it is possible to rotate the entire strain gauge holder towards the back of the instrument and lock it in the rest position. In this way, you can use the entire light between the columns of the instrument to carry out tests even on large pieces.

Instrument Characteristics

Resolution

0,01 mm

Total run

900 mm

Adjustment of Reference lenght

Via the rapid replacement of pre-calibrated spacers (10, 20, 25, 50 mm).

Spacers for different Reference lenghts available on request

Spacers for different Reference lenghts available on request

Closure force of the tweezers

Adjustable closure spring

Gibitre Instruments

Via dell'industria, 18

Bergamo (Italy)

te. +39 035 461146

www.gibitre.it

info@gibitre.it

Copyright Gibitre Instruments